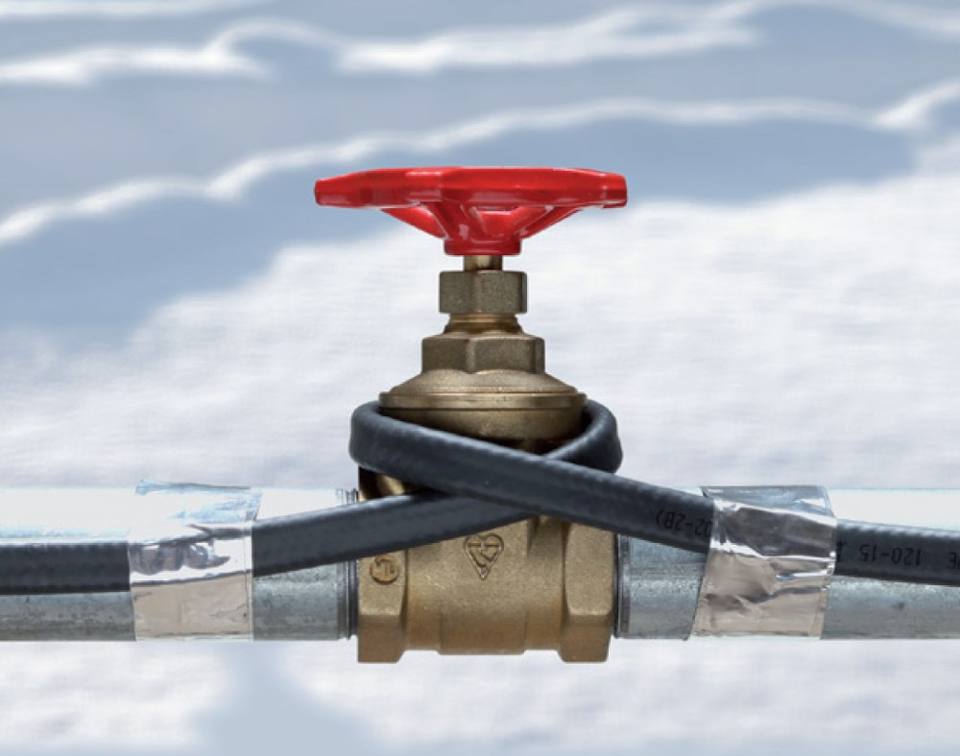

Corrosion-Resistant and Explosion-Proof Polyolefin Insulated Heating Cable

No reviews yet

Attributes

tinned copper wireConductor Material

PolyolefinInsulation Material

PVC,PE,PTFEJacket

twin conductorNumber of Conductors

Anhui, China (Mainland)Place of Origin

DWL-PF46Model Number

Brand Name:Anbang

Application:industrial,construction

Length:200m, 1 m

Maximum maintain temperature:65℃

Maximum exposure temperature:85℃

Minimum installation temperature:-40℃

Voltage:110-120V/220-277V

Max resistance of braid:≤18.2Ω/km

Certification:CE,EMC,RoSH,ISO9001

Key attributes

Conductor Material

tinned copper wire

Insulation Material

Polyolefin

Jacket

PVC,PE,PTFE

Number of Conductors

twin conductor

Place of Origin

Anhui, China (Mainland)

Model Number

DWL-PF46

Brand Name

Anbang

Application

industrial,construction

Length

200m(656.17ft), 1 m(3.28ft)

Maximum maintain temperature

65℃

Maximum exposure temperature

85℃

Minimum installation temperature

-40℃

Voltage

110-120V/220-277V

Max resistance of braid

≤18.2Ω/km

Certification

CE,EMC,RoSH,ISO9001

Packaging and delivery

Selling Units

Single item

Single package size

11X5.6X10 cm

Single gross weight

0.080 kg

Lead time

Customization options

Customized logo (Min. order: 5,000 meters)

Customized packaging (Min. order: 5,000 meters)

Graphic customization (Min. order: 5,000 meters)

View details

Product descriptions from the supplier

Warning/Disclaimer

California Proposition 65 Consumer WarningView more

Customizable

Minimum order quantity: 100 meters

$0.51-0.72Variations

Select nowNumber of Cores

2-core

Customization options

Customized logo (Min. order: 5,000 meters)

Customized packaging (Min. order: 5,000 meters)

Graphic customization (Min. order: 5,000 meters)

Shipping

Shipping fee and delivery date to be negotiated. Chat with supplier now for more details.

4 interest-free payments with

Alibaba.com order protection

Secure payments

Every payment you make on Alibaba.com is secured with strict SSL encryption and PCI DSS data protection protocols

Money-back protection

Claim a refund if your order doesn't ship, is missing, or arrives with product issues